Call for Pricing

Reduced labor, increased safety, the benefits just keep stacking up.

Stacking wall panels at the end of your production line can be a real labor-intensive and safety-challenging task. But it doesn’t have to be now, thanks to ProStack. This innovative wall panel stacker literally stacks from the bottom up, reducing awkward overhead lifting & placement, and the risk of head injury. Plus, ProStack frees up at least one worker to return more productively to your core task—building wall panels. Enhanced worker safety and productivity is what ProStack is all about.

Setup and installation is easy too, without the need for complex training or disruption to workflow. So free up your team to do what they do best, and you need to do most, and let ProStack stack your wall panels instead. ProStack can even operate with your existing powered conveyors or select our optional matching conveyors (see the video shown below). 208 volt, 3 phase, 43 Amp base model electrical required. No air required. Footprint is 26′-5″L x 19′-3″W.

- Wall Length Max – 16’

- Wall Height Range – 8’ to 12’

- Material 2×4″ through 2×8″

- Total Weight capacity – 6,000 lbs.

- Total stack Height Max – 6’

- This unit stacks on-center

- System is able to stack on-center layers that have multiple wall segments

- Allows wall stack layer lengths to 20′

- Siemens® HMI touch-screen controls

- Full manual override controls via HMI

- Speed – 45-60 seconds per wall layer

- Wall entry height into ProStack and exit discharge height are set by HMI

- NO overhead components = no overhead hazards or annual inspections

- Modular design for quick and easy self-installation. Manual override via HMI. Safety barriers. No floor anchors required.

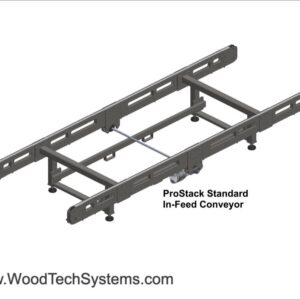

For maximum efficiency consider these ProStack conveyor system options.

ProStack Wall Panel In-Feed Conveyor:

ProStack powered in-feed conveyor was engineered to deliver wall panel segments at a matched speed and height into the ProStack automated wall panel stacker. Built for smooth operation and assembled with laser cut, powder-coated finish steel. Base model conveys wall panel segments up to 12’ in height and up to 16’ in length for wall segments up to 1,600 lbs. Extended length systems come in standard 20′ and 24’ length capacity. All models come with adjustable working heights and variable conveyor speeds.

ProStack Wall Panel Tilt In-Feed Conveyor:

Solving the problem of missed fasteners on exterior sheathing remains one of the primary reasons for call back charges and exceptions noted during jobsite building inspections. Clearly finding and resolving missed fasteners or “shiners” becomes mission critical before a sheathed wall panel leaves the production line and into the ProStack. Our shop-proven, tilting conveyor makes the process safe, fast, and labor efficient. The ProStack tilt in-feed safely lifts wall segments to 45º in 5 seconds for inspection and on to 75º for easy to reach repairs. This tilt system is also excellent for installing blocking, windows and other details in your wall panel segments:

ProStack Tilt In-Feed Conveyor: System can tilt wall panels to approx. 75º for working access to install blocking, windows, or inspection/repair of “shiners” on sheathed wall segments. System utilizes hydraulic power from an existing ProStack wall panel auto-stack system (required).

Wall Length Max –16’, Wall Height Range– 8’ to 12’, Material 2×4’ through 2×8’, Total Weight Capacity – 1,200 lbs., Electrical and manual safety redundancy, Pendant operator control, 208v/3Ph electrical, no air required.

Powered Out-Feed

Conveyor section, full-width, HD roll-top for easy access to banding operation. 12’W x 16’L, adjustable working height from 28” to 34”. 208 volt, 3 phase, 52 Amp electrical required.