DAK Automation

DAK Automation designs and builds wall panel equipment from a component manufacturer’s perspective. Proudly manufactured in North Dakota, USA.

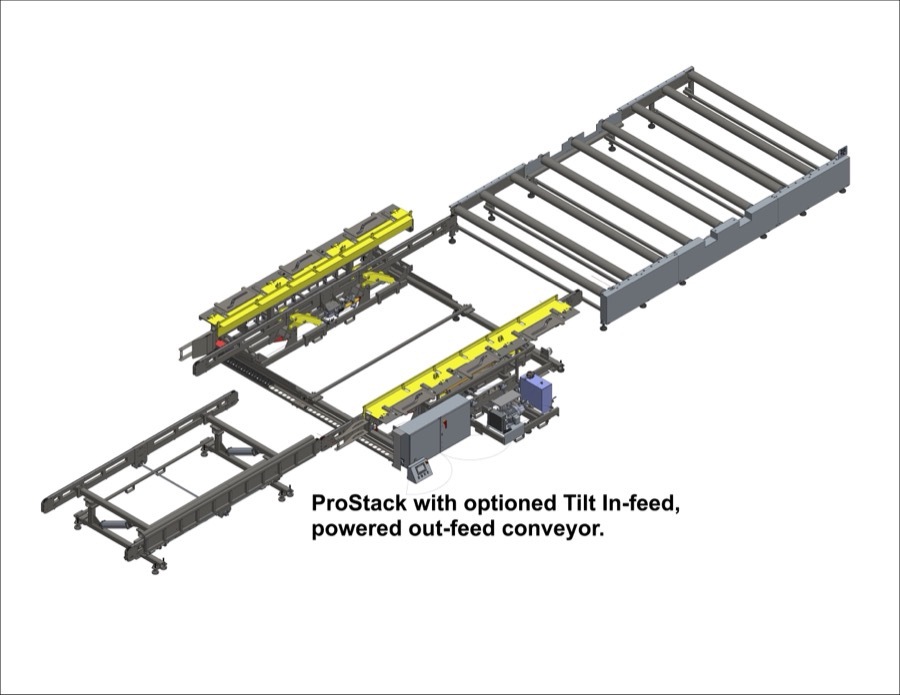

ProStack

ProStack is the best way to safely stack completed wall panels coming off the production line. Since the panels are moved from the bottom edges, the panel is never at head height and the mechanical lift system minimized access for fingers being injured during the stacking cycle. ProStack is able to stack on-center layers of wall panels with multiple wall segments, including forklift pockets.

The ProStack basics include:

-

- Wall heights from 8-ft to 12-ft (nominal).

- Wall lengths from 20-ft to 24-ft.

- Wall widths from 2×4″ through 2×8″

- Weight capacity of 6,000 lbs.

- Stack height of 6-ft.

- Speed of 45 to 60 seconds per wall layer.

- On-center stacking.

- Siemens controls via HMI touchscreen.

- Manual override to controls.

- Reliable, quiet, industrial hydraulics.

- Customer installed / Plug & Play design.

First introduced in 2021, ProStack is the proven design for wall panel facilities with options for stacking wall panels with up to 18″ overhanging sheathing, powered infeed, tilt infeed for quickly checking and correcting “shiners”, and powered outfeed.

Requires 208 volt, 3 phase, 60 Hz, 46 Amps (full-load) electrical supply.

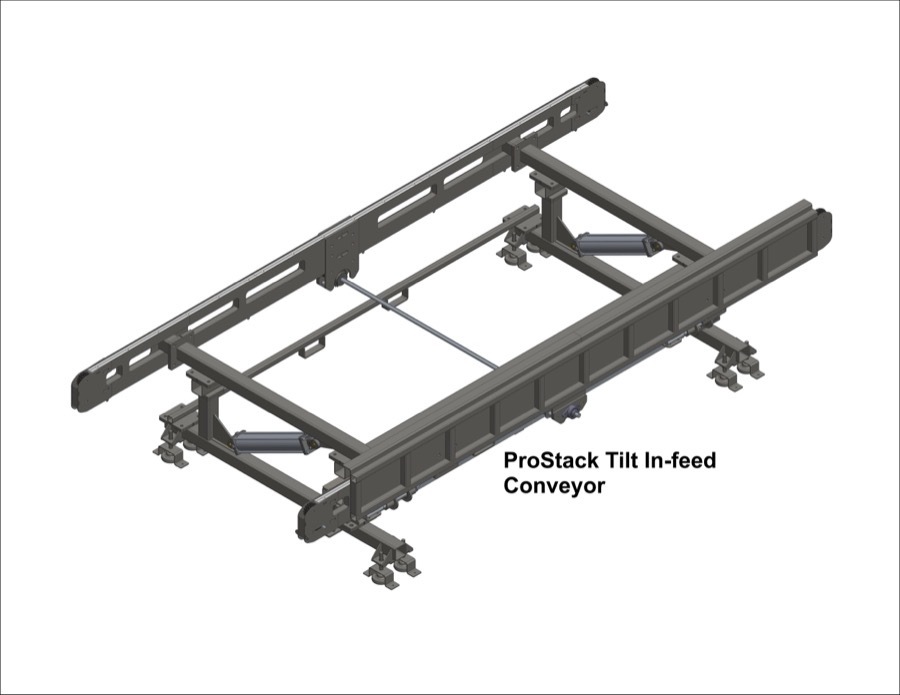

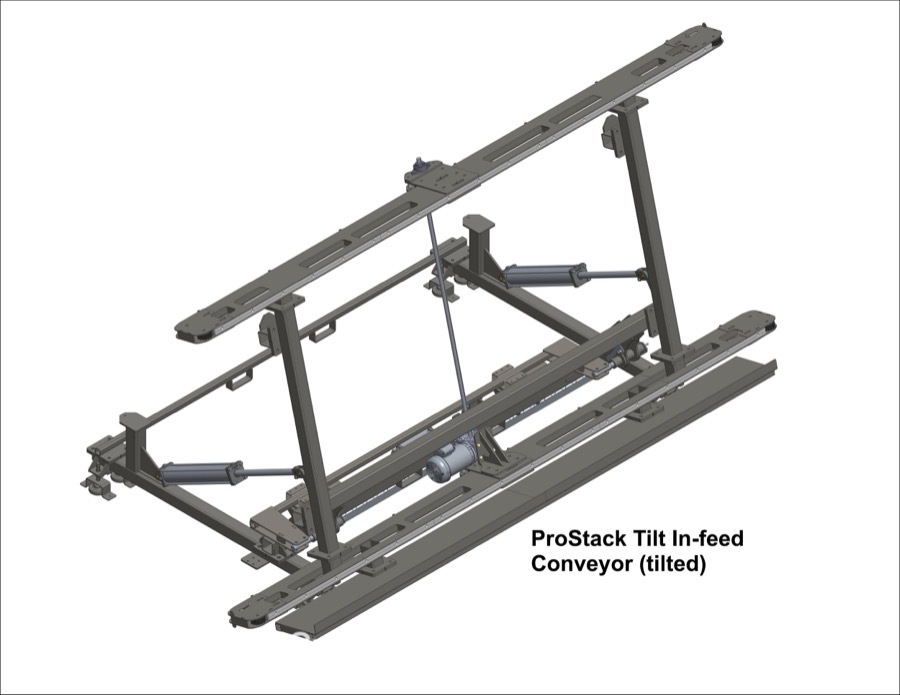

ProStack Wall Panel Tilting In-Feed Conveyor

Solving the problem of missed fasteners on exterior sheathing remains one of the primary reasons for call back charges and exceptions noted during jobsite building inspections. Clearly finding and resolving missed fasteners or “shiners” becomes mission critical before a sheathed wall panel leaves the production line. Our shop proven, tilting conveyor makes the process safe, fast, and labor efficient. The ProStack tilting infeed safely lifts wall segments to 45º in 5 seconds for inspection and on to 75º for easy to reach repairs. This tilt system is also excellent for installing blocking, windows, and other details in your wall panel segments.

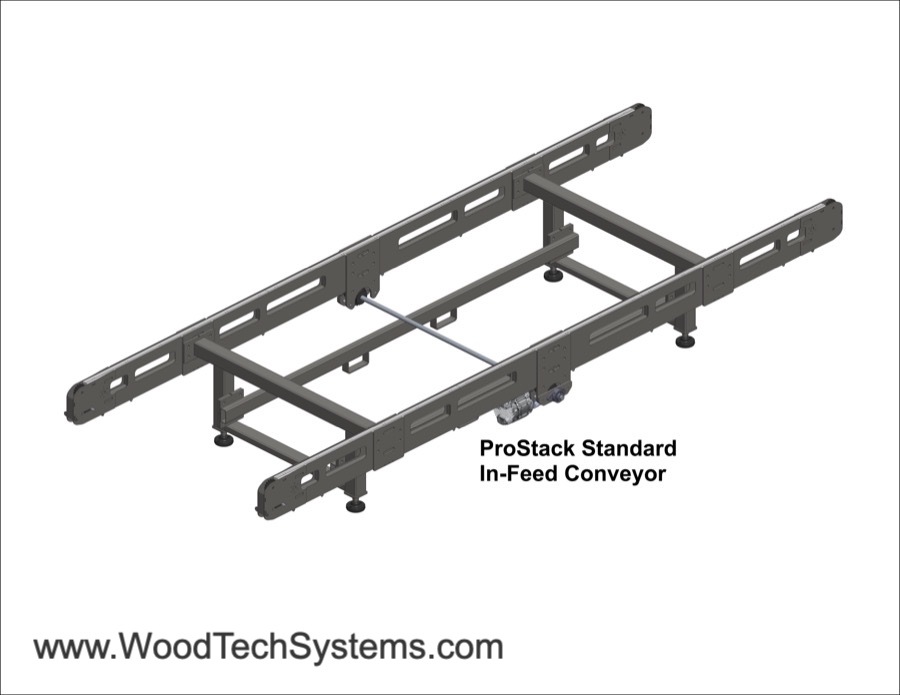

ProStack Wall Panel In-Feed Conveyor

ProStack powered in-feed conveyor was engineered to deliver wall panel segments at a matched speed and height into the ProStack automated wall panel stacker. Built for smooth operation and assembled with laser cut, powder coated finish steel. Base model conveys wall panel segment up to 12’ in height and up to 16’ in length for wall segments up to 1,600 lbs. Extended length systems come in standard 20 ft. and 24’ length capacity. All models come with adjustable working heights and variable conveyor speeds.

Equipment for sale:

ProStack Wall Panel In-Feed Conveyor

ProStack Wall Panel Tilt In-Feed Conveyor

ProStack Wall Panel Stacker

Call for Pricing