2019 H & M, MBA wall panel assembly station – Station includes (1) wall panel combination extruder (model X-Multi) set up with (2) horizontal Paslode Powermaster nail guns and a multi-function bridge including (2) nailing tool holders, a router and vacuum. One carriage on the bridge is equipped with an ITW CW650.7010 sheathing nailer and the other with an ITW S640.5210 staple gun and batten unit. The 7m butterfly station (model X-Tilt) receives panels from the combination extruder for easy flipping. Station builds from 4’-1” to 11’-10” tall wood wall panels to 23’ long, using 2×4, 2×6, 2×8 and 2×10 dimensional lumber.

From the OEM’s brochure:

“Combination Table – The X-Multi is a complete assembly machine which combines all the functions of a framing station and nailing bridge into one machine [run by] one operator to achieve speeds up to 15 lm/h (framing and cladding only). As each panel is clamped from the first nail of the initial stud, to the last nail in the cladding, the Mobi-One ensures that even the most complex of panels are manufactured accurately and efficiently. Drop down pins keep the panel square as it is manufactured.” Includes laser alignment for stud nailing, pneumatic cable reel and tool holder, two tool holders for CNC nailing of the wall panel, tools on bridge for framing and sheathing in one location. Used for both sub assembly and angled panel manufacturing.“

“Multi-function Bridge – A fully automatic station for the fixing of sheathing. Nailing / stapling operations can be completed accurately from data downloaded from the CAD package via our Design2Frame software. Multiple tools can be fitted to either one or two CNC carriages which can operate simultaneously to increase element throughput.”

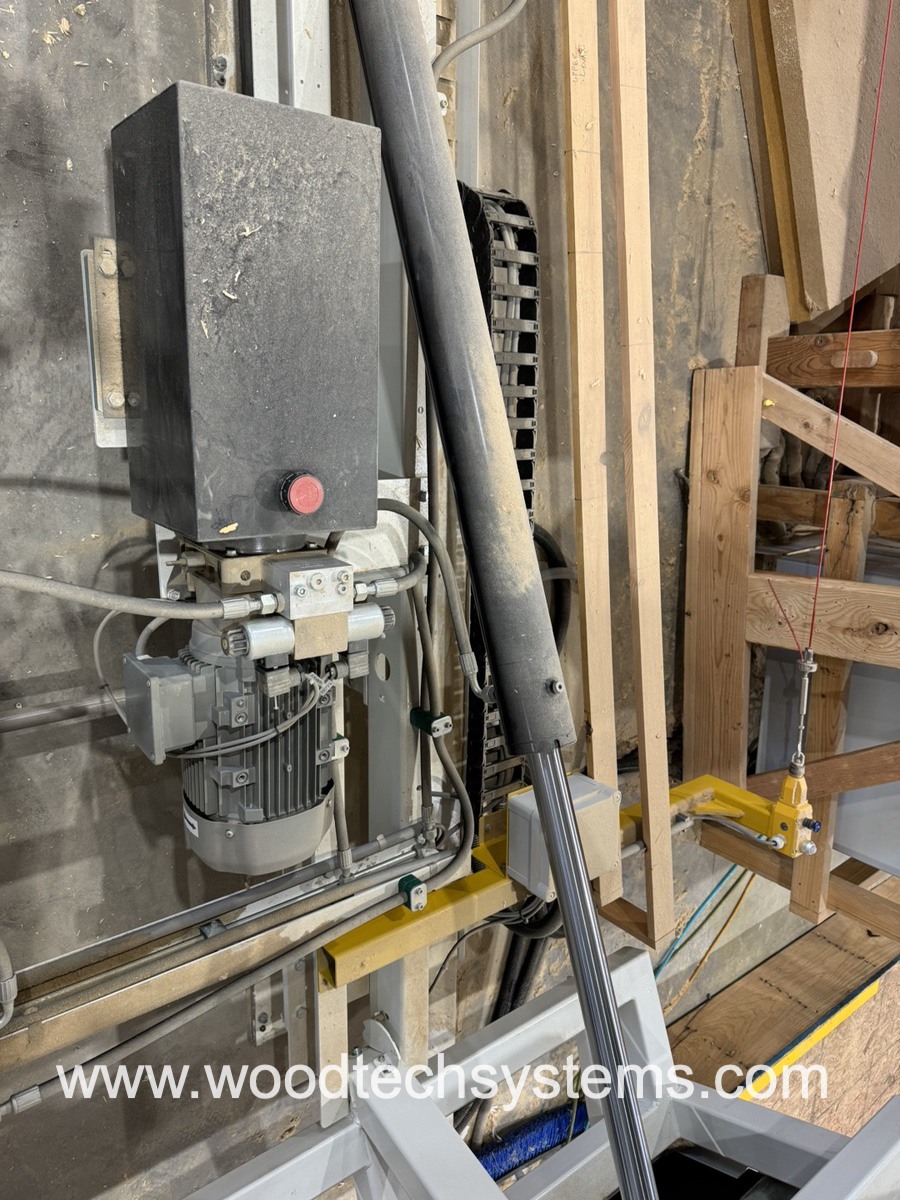

“Butterfly Station – A pair of hydraulically operated tables which enable the panels to be brought to the vertical position, passed to the 2nd table, and safely lowered back down on the opposite side for fitting of insulation and closing of the panel. The hydraulic lifting of the tables is controlled by a 4kw motor with fail safe locking cylinders, a floor mounted control unit featuring push button operation as well as a wireless remote control. Includes (25) vertical infeed rollers, and (20) horizontal outfeed rollers for side-ways discharge.”

Table includes any available platforms, rams and stands. Bridge includes all available sheathing nailers, router tool and on-board dust collection. Requires Design2Frame software to convert other customer file types into .MOB files. Computer running Windows 10 Pro. Includes any available spare parts and nail coils. North American support provided by Akhurst Machinery and OEM support available at an additional cost. Sold for $259,000 new. 400 Volt, 3-phase electrical required. 145 PSI air required.

Please see the following drawing: Dwg-10524-1-MBA Equipment Floor Plan & Axo